Featured on Home Page

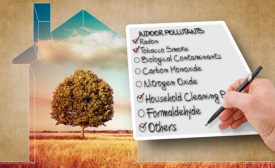

Home Indoor Air Quality (IAQ) assessments present challenges

Today’s indoor generation

July 5, 2018

ISHN’s Guide to Breakthrough Training Resources

Online, mobile, micro-learning, podcasts and more

July 1, 2018

Regularly assess risks- discomfort, pain and working conditions- to the feet

Stay on your toes

June 28, 2018

Q&A with new ASSE/ASSP president

Rixio Medina oversees transition to the organization’s new name

June 26, 2018

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing