Featured on Home Page

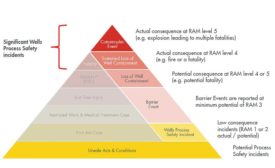

Process safety & personal safety in oil well drilling

Performance indicators catch problems before becoming events

June 1, 2017

How to find the best footwear fit for specific hazards

The sole of construction

June 1, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing