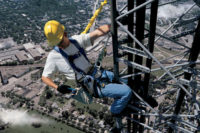

Guard workers from danger

Deploying an effective fall protection program can be a challenge at any job site, and the potential hazards only increase when it’s necessary to enter a confined space.

For workers who enter confined spaces, such as crawl spaces, vaults, tanks, tunnels, pipelines, silos or manholes, the selection and proper use of fall protection equipment is especially critical. This is because there is more to a confined space than meets the eye. For instance, the area may appear safe, but in a restricted environment there may be fall hazards, entrapment hazards, engulfment hazards, atmospheric hazards or other serious safety hazards that greatly increase the danger a worker may encounter when entering the space. A confined space is any space with limited means of entry or exit that is large enough for a person to enter to perform work but is not designed for continuous occupancy. There are two basic categories of confined spaces: those that require a permit and are regulated by OSHA, and those that do not. Permit-required confined spaces fall under the OSHA §1910.146 and are defined as spaces that have one or more of the following dangers:

- Contain or have the potential to contain a hazardous atmosphere.

- Contain a material that has the ability to overcome an entrant.

- Contain an internal design in which a worker could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and narrows to a smaller cross-section.

- Contain any other recognized serious safety hazard, such as a fall hazard.

All spaces designated as permit-required confined spaces require a company to implement a safety program that is in compliance with OSHA §1910.146. This program must be in writing, and regulations require issuing entry permits, selecting an entry attendant and having a rescue plan. The company is also responsible for proper employee training on confined space entry and providing proper personal protective or fall protection equipment.

GUARD workers with PPE

During an emergency, the effective use of equipment can mean the difference between injury and safety, or even between life and death. When choosing proper personal protective equipment for confined space entry, think of these characteristics to GUARD workers from danger:

G for Ready to Go. If the job site lends itself to the use of a portable device, one should be considered if possible. A lightweight, easy-to-assemble system is always preferable because it is simple to set up and transport - it’s always ready to go. Also, a system that makes storage hassle-free helps when the work is complete.

U for Useable. A confined space system should be user-friendly. In the event of an emergency, every second counts. If the crew is fumbling with equipment, valuable time will be lost. The system must operate smoothly, and workers must feel confident using it.

A for Adaptable. The system should be adaptable for uneven terrain and extreme weather conditions. The crew never knows what challenges a work environment may bring. The confined space system should also be adjustable and versatile, preferably with a modular design that permits additions and replacements over time.

R for Rated for Correct Use. Personal protective equipment must be rated for the application for which it will be used, such as fall arrest, material handling or rescue. Choose a system that will maximize strength and minimize weight whenever possible.

D for Durable. A confined space system should be durable, composed of materials strong enough to withstand exposure to harsh environments and regular wear and tear.

OSHA considers open hatches to a confined space entry an unprotected side or edge, which therefore must be addressed for safety. For example, when a hatch or cover is removed to provide access to a confined space, as is the case with manhole covers, the opening must be immediately guarded with a railing, temporary cover or some sort of barrier to prevent an accidental fall into the space. Depending on the type of fall protection system used, it may also be used for non-entry rescue

ABCs of fall protection

When selecting fall protection equipment, keep in mind the three basic pieces of equipment needed for confined space entry, or the “ABCs” of fall protection:

A for Anchorage. There are many anchorage options, starting with a tripod. Tripods are easy to transport and set up, but they don’t fit all opening sizes. A davit arm or davit post comes in handy because they have different base configurations. Davit systems are available in either fixed position or portable bases. Further, a counterweight system can be employed when access to a confined space prohibits the use of a tripod or davit arm. Finally, if the job site requires entering a confined space horizontally rather than vertically, a side-entry system is needed. This system uses clamps to the access point to allow an anchorage and base for attaching a winching device.

B for Body Support. Consider body support, including specialized harnesses available for confined space entry, which have D-rings on the top of both shoulder straps and a Y-lanyard to connect the two D-rings to a winch line. This enables the worker to be raised or lowered in a vertical position. In comparison, a traditional harness with a dorsal D-ring attached to a winch line would result in the worker being raised or lowered on a diagonal, which can be challenging in a confined space. Lastly, a full-body harness that is both durable and comfortable for the worker is preferable.

C for Connector. Consider the connector, which is a winching mechanism in confined space entry. A winch, such as a steel or synthetic line and crank, connects to the tripod or davit system to lower and raise the worker. Winching devices allow the crew to lower or lift each other easily and also feature a braking system. In the event that the winch operator loses control of the crank, the worker being transported will not fall. Some winches have a power drive that allows the crew to operate the device manually or automatically, which can be beneficial when it is needed for long periods of time.

Proper equipment selected with careful consideration of the application can make a big difference when working at any job site. Making sure that all workers are trained on how to use PPE is essential for keeping the whole crew safe while working in a confined space

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!