Training

Invest in workers to prevent absenteeism, cut operating costs

Preventative training is essential when there is risk of workplace injury

Every chief executive is concerned with the bottom line and not for no reason. Reducing operating costs to maximize profit is the fundamental goal of any successful business. A poor profit margin can sink even the most promising of companies.

Expenses are an unavoidable reality and the cost of doing business. The trick is to pick the right things to spend money on, to maximize revenue and minimize cost. In the post-COVID era absenteeism has skyrocketed in many industries, becoming a key focus for executives who want to bring down costs.

Smart leaders know that investing in people delivers results; creating strong, resilient businesses with passionate employees that believe in the work that they do. As Zig Ziglar said, “You don’t build a business, you build people. And then people build the business.”

Absenteeism driving up operating costs

Lost work days are one of the largest business operating costs. Each year, absenteeism costs the US economy as much as $84 billion in direct costs and $225 billion indirectly. In the EU, low attendance rates cost a staggering $470 billion annually.

In 2019, the average absence rate was 2.9% in the warehousing industry, 2.4% in construction and 2.5% in manufacturing.

Yet experts advise that 1.5% is an acceptable absence rate, anything above that is likely to be preventable.

Thus, simply by addressing the preventable causes of absenteeism, it is possible to reduce business operating costs; cutting the absence rate by as much as 42% on average (saving $3.3 billion in the US and $5.1 billion in the EU).

Presenteeism: the flipside of the same coin

On the other hand, the rates of presenteeism (workers on the job with a medical illness or injury) are even higher. Researchers estimate that in the last 12 months, approximately 40% presented to work despite feeling pain or being otherwise unwell.

In days past, soldiering on may have seemed like a good thing, even resulting in praise and recognition, but today savvy businesses know that it results in substantial productivity losses.

A problem that is not always obvious, presenteeism flies under the radar, cutting productivity by one-third or more and costing the US economy more than $150 billion every year.

One study found that as many as 79% of construction workers reported presenteeism related to musculoskeletal injury in the last year. Another study estimates approximately 75% of workplace presenteeism was related to musculoskeletal pain.

Simply by targeting musculoskeletal pain it is possible to reduce the rate of presenteeism by 30%, resulting in a cost saving of $45 billion in the US alone.

A preventable cause

All of the statistics can seem overwhelming. You may be wondering how to practically eliminate the preventable causes of absenteeism and presenteeism in your company. The first step in creating a targeted approach is to understand the underlying preventable causes.

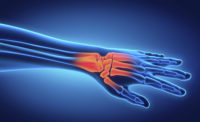

Researchers have identified musculoskeletal pain and injury as one of the leading contributing factors. Addressing ergonomics in the workplace can make a significant impact; leading not only to happier, healthier and more engaged workers but ultimately a direct cost saving that improves the bottom line.

The nature of musculoskeletal pain is a vicious cycle. If a worker is injured or in pain, they are extremely likely to need time off from work; resulting in absenteeism and skyrocketing costs. On the other hand, if a worker suffering from musculoskeletal pain presents to work and pushes to “suffer through,” it could be catastrophic not only leading to significantly reduced productivity but a potentially serious injury.All of this creates a ripple effect of consequences; placing extra pressure on other workers to pick up the slack, increasing the likelihood of costly mistakes. Overall leading to low engagement, a negative work environment and a loss in productivity.

The human cost

Beyond the dollar signs lies something deeper and far more significant; the human cost. In his book, Everybody Matters, Bob Chapman says that “leadership is the stewardship of the lives entrusted to you.” Businesses have a responsibility to their workers not to cause them pain, suffering or disablement and to provide a work environment that fosters well-being.

Addressing musculoskeletal pain and injuries in the workplace is not only about targeting cost savings and improving the bottom line but it is also about responsible leadership; minimizing the human cost of doing business.

The key to unlock savings

Underneath the surface of it all lies proprioception; a fundamental concept of ergonomics and a key to a targeted approach to musculoskeletal pain and injury that can deliver real cost savings.

In simple terms, proprioception can be described as knowing the position of the body in space. It is the ability to sense where any part of the body is positioned at any particular time without looking in a mirror or observing.

But skilled proprioception does not come naturally, it requires practice and training. Think of dancers, elite athletes and sports people and their ability to perform with precision; their proprioceptive sense has been exercised and developed and the feedback loops to the brain are aligned. They are aware of how they are moving, where their limbs, spine and all areas of their bodies are in space at any point in time and therefore have less chance of experiencing disablement.

Investing in training that develops this proprioceptive sense of workers is one of the keys to unlocking ergonomic success; reducing the number of hazardous movements in their day to day lives, eliminating musculoskeletal pain and injury and ultimately cutting down absenteeism and presenteeism.

Training the brain

The question then remains; how can workers be trained to develop their proprioception? The answer is simple, learning tools that expand movement awareness; incorporating reminders, biofeedback, on-the-go micro-learning, reflective processing, and cleverly integrated awareness and corrective exercises.

Ongoing practice can reorganize the neural pathways and realign muscles, joints and balance. Providing workers with education, training and the opportunity to practice proprioception on a regular basis promotes a far greater chance of moving safely, improving performance and preventing injuries over the lifespan of their career.

Expand awareness through technology

Today, there is a simple solution that can train workers to improve proprioception, reducing hazardous movements and addressing musculoskeletal factors that underpin lost work days and presenteeism.

Researchers have found that investing in wearable safety technology can reduce lost work days by over 70%. Technology can give workers the opportunity to take ownership of their own safety, making them much less likely to take time off and much more likely to feel engaged on the job, creating a more efficient, more productive workplace.

Advances in ergonomic training using sensors and biofeedback are providing an opportunity for workplaces to leverage the power of artificial intelligence to expand the proprioceptive awareness of workers through flexible training that track hazardous movements on the go.

AI-wearable technology and training programs that target staff retention, absenteeism, engagement and productivity through improving ergonomic safety in the workplace are charting the course for the future. Providing technology solutions that strive to ensure that workers are not only at work but that when they are, they are working and feeling well.

The solution is simple; small, lightweight wearable devices designed to monitor the behavior of workers and alert of any hazardous movements that could lead to back or shoulder injuries. These alerts improve awareness and reduce the overall risk of injury. Track progress, complete training modules, analyze data and produce visually appealing reports through mobile apps and centralized dashboards to target and reduce ergonomic risk.

Ultimately, the cost of safety technology is a small price to pay for significant cost savings, both in the economic and in the human sense.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!