Indoor air quality (IAQ) refers to the air quality within and around buildings and structures, especially as it relates to the health and comfort of building occupants. Inside air can affect a person’s well-being and ability to work. Temperature, humidity, amount of outside air, mold and airborne contaminants all play a role in IAQ. People may experience health effects from indoor air pollutants soon after exposure or years later.

This article will look at IAQ health risks related to dust and mist generated from manufacturing processes, safety guidelines and ways to correct poor air quality.

Before digging deeper into some of the issues related to IAQ, here are a few interesting facts to consider. A human being breathes in about 2,000 gallons of air each day. According to the EPA, Americans spend approximately 90 percent of their time indoors, where levels of pollutants may be two to five times — and occasionally more than 100 times — higher than outdoor levels. The EPA consistently ranks indoor air pollution among the top five environmental risks to public health. The Occupational Safety and Health Administration (OSHA) notes that millions of workers are required to wear respirators in workplaces throughout the U.S. to protect against harmful dusts, fogs, smokes, mists, gases, vapors, sprays and insufficient oxygen levels.

Quality control issues affected by IAQ

Poor IAQ affects employees, systems and productivity. For example, unseen dust remains suspended in the air for long periods of time, then migrates to HVAC systems, causes poor air flow and is reintroduced to employees. Maintaining a healthy workplace with good IAQ can improve employee well-being, retention and productivity. Research has shown that spending just $40 per person a year on IAQ results in a $6,500 increase in employee output.

Inadequate IAQ also impacts equipment and can cause downtime while waiting for repairs or replacements. Smaller particulates can stay suspended for days, eventually finding their way to air-moving devices such as HVAC equipment, causing it to work harder but less efficiently and requiring more frequent filter change-outs. In addition, dust on condensers can breed bacteria and mold creating a musty smell, and dust on heating coils can be fuel for burning smells. Accumulation of dust can cause electrical devices to overheat and reduce contact in relays and switches. Dust combined with a small amount of moisture can corrode vital equipment components, especially electrical motors.

IAQ also affects workplace housekeeping. Mindful IAQ practices can reduce the cost and frequency of housekeeping, as well as reduce injuries. Dust and mist that settle on surfaces create slipping hazards. Slips, trips and falls cause more than 700 fatalities per year and more than a quarter of a million nonfatal injuries involving days away from work, according to the Bureau of Labor Statistics.

Health risks related to poor IAQ

Symptoms from poor IAQ can easily be confused for other illnesses, like colds, allergies and influenza. Headaches, coughing, sneezing, eye irritation, dizziness, nausea, fatigue, respiratory or sinus congestion and skin irritation can be caused by, but are difficult to attribute to, IAQ. If employees notice improvement after leaving the facility, then those symptoms might be related to poor IAQ in the workplace. However, more severe health-related issues, such as respiratory diseases, heart disease and cancer may surface years after exposure has occurred.

Common causes of contaminated air

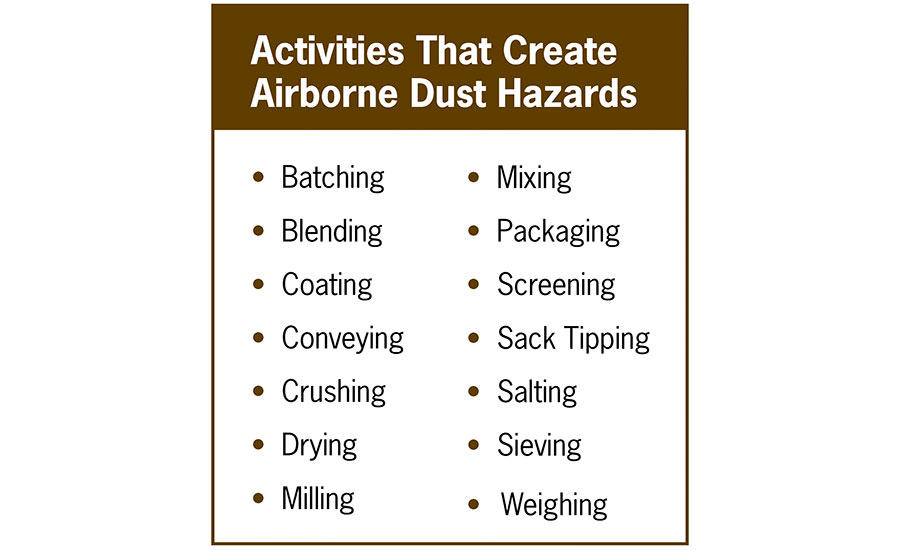

Industrial dust, also known as process dust, is generated during a facility’s manufacturing or processing operations such as cutting, drilling, grinding or sawing. Process dust can also come from materials, chemicals or ingredients used in the production process such as flour, sugar and pharmaceuticals. Operations like welding and plasma cutting also produce tiny particles that are generally called “fumes” or “smoke.” Wet airborne particles are called “mist.”

Industrial processes that generate dust include metallurgical work, welding, plasma and laser cutting, abrasive blasting, glass and ceramics manufacturing, chemical processing, food processing, pharmaceutical solid dose manufacturing, woodworking, extrusion of plastics and metals, and weighing, bagging, and transporting powdered materials.

Other factors that contribute to poor IAQ include poor HVAC maintenance, inadequate fresh air, contaminants from outside, dampness and moisture, and using compressed air for housekeeping.

Regulations and guidelines covering industrial dust

OSHA General Duty Clause Section 5(a)(1) stipulates that it is an employer’s responsibility to identify and abate hazards in the workplace. OSHA requires employers to keep records that identify all the dust generated in their facility. If the dust is flammable or explosive, then National Fire Protection Association (NFPA) standards are followed to manage the dust.

OSHA has set permissible exposure limit (PEL) thresholds for airborne contaminants in the workplace. If air quality testing shows that your facility is no longer meeting OSHA exposure limits, you are exposing your workers to poor IAQ. OSHA has established PELs based on an eight-hour time-weighted average (TWA) for hundreds of dusts, and they are listed in OHSA’s annotated PEL tables Z-1, Z-2 and Z-3.

National Institute for Occupational Safety and Health (NIOSH) provides recommended exposure limits (RELs) for hazardous substances, including dusts, which tend to be stricter than OSHA PELs. NIOSH RELs are not regulatory requirements but are recommended guidelines for upper exposure limits.

Correcting poor IAQ

If your process cuts, machines, shapes or alters raw materials in a way that creates dust or mist, those materials are being distributed into your facility’s air. All of the potential sources of dust, mist and fumes are capable of having an engineered control system to protect workers.

An industrial dust collector gathers nuisance and hazardous particles from the air before they can settle on surfaces.

When dealing with toxic, combustible or other dangerous airborne contaminants, there are many factors that impact the proper design of dust and mist collection systems. These include the type of capture system, particle size, how the dust is generated, type of filtration media, exposure through maintenance and proven success of the dust collection system in the field.

A cartridge dust collector is an industrial dust collector that uses highly efficient cartridge-style filters to collect and filter dust. As the filter cartridges become loaded with dust, the collector automatically cleans them using a pulse of compressed air. The pulse of air expels the dust from the cartridge, sending it into a disposal bin called a hopper. This process greatly extends the life of the filter cartridges, but they eventually need to be replaced with new ones.

Factors like dust size, shape and combustibility help to determine the right type of filter. Testing a sample of dust is the only way to get an accurate assessment of its properties. Dust testing is available at independent laboratories and equipment suppliers. Extended-life filters might be more expensive up front than standard filters, but they stay cleaner and last longer, resulting in fewer change-outs and more uptime.

Additional measures to improve IAQ include increasing the amount of fresh air supply to dilute the buildup of inside contaminants. It is important to follow ASHRAE 62.1-2007 recommendations regarding separating air intakes and exhausts. Also, verify the facility’s pressure relative to outside because buildings under negative pressure could cause drains, stacks or exhaust vents to run backward.

In addition to maintaining your dust or mist collection equipment to ensure it is operating properly, you should take proper care of HVAC equipment to make sure you are using the correct filters and that they are changed regularly.

Final thoughts

If your facility’s manufacturing processes generate hazardous dust, one of your top priorities is to ensure healthy IAQ. Dust must be properly collected and contained to protect worker health and meet regulatory compliance. Your IAQ game plan should include knowing the types of particulate matter your operation generates, understanding the risks these particulates have on human health, following regulatory guidelines and selecting the right collection system and filters for the job.

References

OSHA:

https://www.osha.gov/SLTC/respiratoryprotection/

https://www.osha.gov/dsg/annotated-pels/

EPA:

https://www.epa.gov/iaq-schools/why-indoor-air-quality-important-schools

https://www.epa.gov/indoor-air-quality-iaq

https://www.epa.gov/indoor-air-quality-iaq/introduction-indoor-air-quality

https://www.epa.gov/report-environment/indoor-air-quality

American Lung Association:

https://www.lung.org/about-us/blog/2017/07/how-your-lungs-work.html

Economic, Environmental and Health Implications of Enhanced Ventilation in Office Buildings, Int. J. Environ. Res. Public Health 2015, 12(11), 14709-14722:

https://doi.org/10.3390/ijerph121114709

Bureau of Labor Statistics: