What are the Elements of a Compliant Safety Sign?

Workplace safety signs are regulated by the Occupational Safety and Health Administration (OSHA) under standard 1910.145 (Specifications for accident prevention signs and tags). The safety sign elements outlined in standard 1910.145 are determined and legally enforced by OSHA, meaning failure to include any one of them in your safety signage could land you a citation come inspection day.

Complying with safety sign legal requirements certainly helps create a safer work environment for your employees, however, it’s more of a baseline rather than the "gold standard" of safety practices. The American National Standards Institute (ANSI) has developed additional voluntary standards for safety signage that are not legally enforced, but can help make the safety signs in your facility more effective. The primary ANSI document for Safety Signs is ANSI Z535.2 – Environmental Facility and Safety Signs. This document provides guidelines for the design, application and use of safety signs in facilities and in the environment through consistent visual layout.

The complete ANSI Z535 series of documents are listed below:

- ANSI/NEMA Z535 Color Chart

- ANSI/NEMA Z535.1 Safety Colors

- ANSI/NEMA Z535.2 Environmental Facility and Safety Signs

- ANSI/NEMA Z535.3 Criteria for Safety Symbols

- ANSI/NEMA Z535.4 Product Safety Signs and Labels

- ANSI/NEMA Z535.5 Safety Tags and Barricade Tapes (for Temporary Hazards)

- ANSI/NEMA Z535.6 Product Safety Information in Product Manuals, Instructions and Other Collateral Materials

It should be noted that while ANSI is not a government agency (and cannot set or enforce laws), legally enforced OSHA standards often incorporate ANSI standards by reference. And in litigation, ANSI standards can sometimes be interpreted as implicit regulations— having voluntarily incorporated them in your safety signage safeguards against this scenario.

There are four regulated safety sign elements that must be present in order meet OSHA standards for accident prevention signs. When creating safety signage for your facility it’s important to include all four elements as a baseline for compliance.

Signal Words & Color Codes for OSHA/ANSI Safety Signs

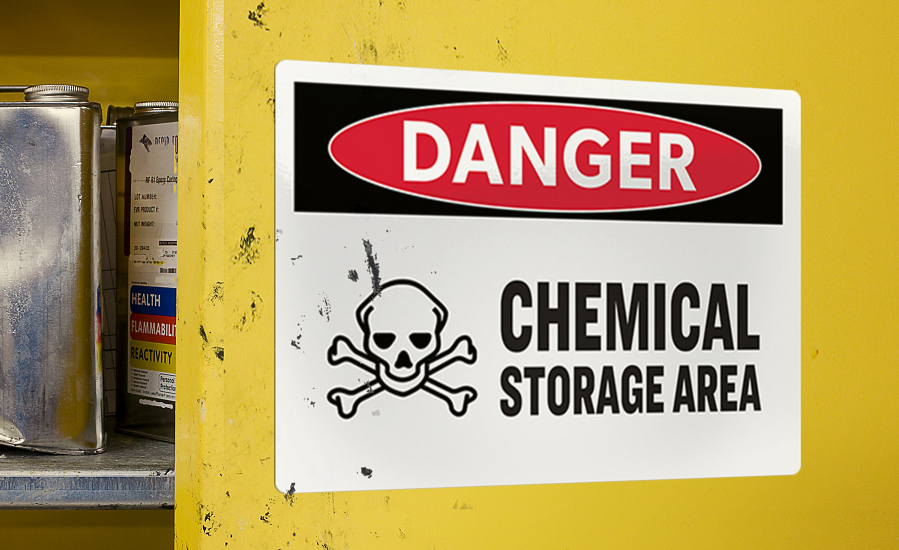

The color code and signal word on a compliant safety sign are inextricably bound together. This is because both OSHA and ANSI designate specific colors for each type of hazard. OSHA requires three types of safety signage signal words: Danger, Caution and Instruction.

For example, OSHA-compliant Danger signs must feature the signal word "DANGER" on a red field, in black text. A compliant Danger Safety Sign cannot have a field of blue, green, orange or any other color besides red.

Caution Safety Signs must feature the signal word "CAUTION" on a yellow field with black letters. Safety Instruction Signs do not have pre-designated signal words as instructions may vary (for example Emergency Eye Wash or First Aid signs. However, these types of safety signs must feature white text on a green field.

Language & Font: Safety Sign Text Elements

OSHA regulation 1910.145(e)(2) provides a guide on the nature of the wording used on safety signs, stating "the wording of any sign should be easily read and concise. The sign should contain sufficient information to be easily understood." In other words, safety signs should be in plain language and to the point.

The interpretation of this regulation also influences the types of font that should be used on safety signage. As all wording on safety signs must be "easily read" it follows that the font must be visually simple so that the text is easy to read. Sans serif fonts are ideal for creating easily readable safety signs.

Placement: A Guide to Safety Sign Locations

The whole point of safety signage is to alert employees to potential hazards in the workplace so the appropriate measures can be taken to avoid accidental injury and/or health repercussions. This is laid out clearly in 1910.145(f)(3).

Using common sense, it follows that safety signs should be placed near potential hazards. OSHA further clarifies placement of safety messaging (and makes it enforceable by law) with 1910.145(f)(4)(vi). Safety messaging (whether communicated by safety tags or safety signs), must be placed "as close as safely possible to their respective hazards."

Keeping safety signs unobstructed, at eye-level and as near the potential hazard as possible is ideal safety sign placement. Following this rule of thumb upholds not only section (f)(4)(vi), but also relates back to (e)(2), positioning safety signs so that they are easily read.

Size: Standard Size of Safety Signage

OSHA safety signage regulations do not specify specific sizes for safety signs and tags, but 7" by 10" is a good starting point. Section 1910.145(f)(4) simply states that "the signal word shall be readable at a minimum distance of five feet (1.52 meters) or such greater distance as warranted by the hazard."

Setting regulations for focusing on the readability of signal words emphasizes the primary function of safety signs—relaying the safety message to employees. Ensuring workers can see safety signs from a safe distance helps alert them to possible hazards and give them time to respond appropriately before risking exposure to the hazard.

Print Safety Signs and Labels On-site

One way to get compliant quickly and cost-effectively is to print your safety signs and labels on-site. Solutions like Avery® Surface Safe® Sign Labels help you protect your workers in minutes.

Simple, straightforward online software makes it easy to translate your safety expertise and experience into compliant, effect safety signage. Select from hundreds of professionally designed OSHA and ANSI safety sign templates and customize to your needs. Durable Surface Safe adhesive signs can be printed on-demand from your own laser or inkjet printer, and are engineered to stick strong, yet remove cleanly from surfaces like glass, metal and dry-wall.

Source: Avery Industrial: www.avery.com/signs

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!