Heat stress prevention tips

Acclimatization, break schedules, ventilation, clothing & monitoring stress can avoid illnesses and even fatilities.

The topic of worker heat exposure has made headlines across the country in recent years. In January of this year, OSHA leveled a fine of $149,664 for violations of the General Duty Clause in response to the 2018 death of a California Postal Worker. Workers in farming, construction, landscaping, oil fields, utilities, and our military face significant risk to heat related illnesses as temperatures begin to rise.

These are hardly isolated incidents. According to OSHA’s records, there were 30 fatalities related to heat-related illness from 2017-2018. Over the past 25 years, there have been more than 200 recorded deaths.

The culprit: heat stress

Heat stress, the net heat load on the body from the combined contributions of metabolic heat production and external environmental factors, is more than just a nuisance. While there are no OSHA or federal regulations addressing worker exposure limits to heat, the Occupational Safety and Health Act of 1970 dictates that companies must provide a workplace free from recognized hazards.

The hazards have been recognized, and companies are being held accountable. In addition to the potential for fines, workers are uniting to demand companies take heat stress into account during worker shifts.

Prevention, not reaction to heat illness symptoms

Fortunately, with the proper program in place, it is possible to prevent symptoms from even occurring. Acclimatization, work and rest schedules, in conjunction with proper ventilation, clothing and engineering controls, are the key to reducing company risk and promoting worker safety.

Acclimatization to prevent risk

Not all heat stress risks are alike. Acclimatization refers to the incremental adaptions our bodies make (for example circulatory stabilization) in response to gradual increases in heat level exposure. The CDC advises having all new workers and workers returning from an absence of a week or more only work for 20 percent of their normal work period on their first day, with an increase of 20 percent each subsequent day.

Maintaining acclimatization is important as well. It can often be regained within two to three days upon returning to a job site.

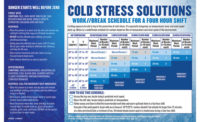

Modified work and rest schedules

Not only should frequent rest breaks be encouraged, they should be scheduled, with water available in shaded or air-conditioned recovery areas. Make sure your workers are properly aware of the determined break schedule, and have co-workers check for heat-related symptoms, such as dizziness, prickly skin or nausea.

It is important to note, however, that air conditioning and shade will not impact acclimatization.

Hazard identification

Appropriately categorizing and identifying hazards is crucial to your heat stress prevention program. Environmental measurements evaluate the ambient environment and its effects on your worker. They include the heat index and wet bulb globe temperature (WBGT). Individual measurements evaluate the heat being generated by your worker, and/or other physiological effects. These include core temperature, heart rate, sweat rate and oxygen consumption.

Monitoring for prevention and safety

WBGT measures heat stress in direct sunlight, taking into account temperature, humidity, wind speed, sun angle and cloud cover. The WBGT index provides work/rest guidelines intended to keep worker body temperatures below 38° C (100.4° F).

Monitoring through WBGT sensing technology allows you to get information on worker heat stress levels, and act accordingly. Being able to quickly and accurately evaluate potential heat stress environments means knowing your worker exposure before they do, which is often far too late.

Having the right instrumentation at your disposal as part of your heat stress protection program allows you to make adjustments to work schedules, develop a proper acclimatization schedule, and appropriately rest your workers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!