Home » Keywords: » welding hazards

Items Tagged with 'welding hazards'

ARTICLES

Innovative safety equipment improves welder protection

Safer & more efficient welding

August 1, 2019

Managing air quality in weld cells

In robotic welding environments, fume levels rise as production volume increases

April 30, 2019

Innovative respiratory protection protects welders like never before

You’ve come a long way, baby

April 24, 2019

3 P’s of Welding Safety: Planning, preparation and protection

Keep these hot tips in mind to improve welding safety – and stay out of hot water

April 12, 2019

Welding robots are on the rise

What’s your strategy? Evaluate risks and select the right safeguarding systems

April 8, 2019

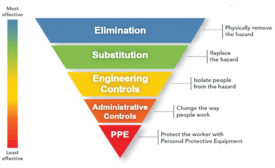

Follow the hazards control hierarchy to reduce welding risks

Back to basics

December 13, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing