Home » Keywords: » dust collection systems

Items Tagged with 'dust collection systems'

ARTICLES

How safe is your dust collection?

6 questions to evaluate safety, risk of deflagration & compliance

August 1, 2019

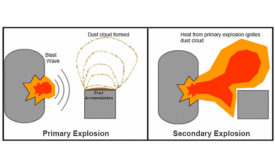

Dust explosion control

Choose the dust explosion protection option that will best protect your systems

March 27, 2019

Damages, injuries, expenses following a combustible dust incident

Be aware of the many losses that can pile up

March 12, 2019

Detecting dangerous combustible dust

Know how to measure levels, mitigate risks & comply with standards to avoid explosions

March 8, 2019

ANSI/ASHRAE Standard 199 improves industrial dust collection

Assess & compare PERFORMANCE

November 1, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing