Home » Keywords: » explosion prevention

Items Tagged with 'explosion prevention'

ARTICLES

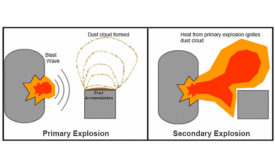

Dust explosion control

Choose the dust explosion protection option that will best protect your systems

March 27, 2019

Detecting dangerous combustible dust

Know how to measure levels, mitigate risks & comply with standards to avoid explosions

March 8, 2019

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing