Home » Keywords: » Safety Data Sheets

Items Tagged with 'Safety Data Sheets'

ARTICLES

Centralized data collection elevates risk prevention

Leverage worker observations

February 3, 2020

7 key features of today’s cutting-edge chemical management software

Game-changing chemical management

August 1, 2019

Centralized software reduces errors & increases security

Ditch the spreadsheets

July 3, 2019

2019 top standards- OSHA Most Frequently Violated Standards

OSHA hazard communication standard

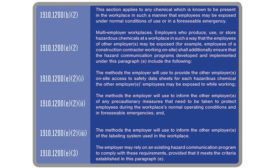

Hazard Communication (1910.1200) OSHA’s hazard communication standard was the second most-frequently cited agency standard in FY 2018.

January 7, 2019

How to develop a robust oversight management program

When contractors come on site

October 31, 2018

EVENTS

Webinar Sponsored Webinars

4/30/24 to 4/30/25

Contact: Amy Jackson

How to Prevent the Most Common HazCom Violations: An In-Depth Look at OSHA Citations!

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing