Home » Keywords: » supply chain management

Items Tagged with 'supply chain management'

ARTICLES

PIP Global Safety selects TrusTrace to support corporate sustainability initiatives

Company prioritizes ESG in workplace protection on new sustainability journey

November 9, 2023

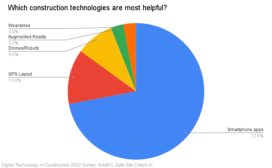

Survey reveals digital transformation is top priority in construction industry

Research conducted by National Association of Women in Construction and Safe Site Check In offers insight into popular digital technologies and impact of the labor shortage and supply chain disruptions

March 10, 2022

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing