Home » Keywords: » machine safety technology

Items Tagged with 'machine safety technology'

ARTICLES

Machine risk assessments vs. safeguarding assessments

Securing your workplace

January 1, 2020

How to de-energize equipment

Force guided relays maintain machine guarding circuit integrity

September 9, 2019

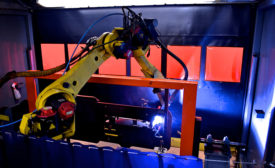

Safeguards for automated operations

Physically protect your workers and minimize the “safety zone” footprint.

May 28, 2019

Five steps to safer machines

A primer on safety technology in standard automation

June 19, 2017

Traumatic machinery accidents carry a heavy price tag

Machine guarding math

March 27, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing