Risk Management

First conduct an assessment, then consider three primary options when selecting a confined space rescue service

Read More

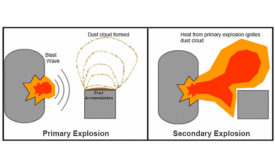

Dust explosion control

Choose the dust explosion protection option that will best protect your systems

March 27, 2019

Hi-Visibility garments continue to evolve

We’ve seen the popularity of lighter, more flexible and breathable segmented trim, and more enhanced visibility by integrating LED luminescence directly on the trim.

March 14, 2019

Damages, injuries, expenses following a combustible dust incident

Be aware of the many losses that can pile up

March 12, 2019

Web Exclusive

Understanding direct and indirect costs of machinery accidents

March 11, 2019

Is the flooring in your building entrance safe?

Protective flooring can create safer spaces by preventing slips, trips and falls and improving the air quality of the building.

March 11, 2019

Detecting dangerous combustible dust

Know how to measure levels, mitigate risks & comply with standards to avoid explosions

March 8, 2019

Wear high-visibility safety apparel

You want to stand out to be seen by drivers when working alongside traffic

March 5, 2019

The hard hat turns 100

Steamed canvas, glue and black paint were used for the original “Hard Boiled” hat

March 5, 2019

Never miss the latest news and trends driving the safety industry

eNewsletter | Website | eMagazine

JOIN TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing