Featured on Home Page

322,000 gallons of hazmat released

NTSB: Derailment shows need for use of safer rail tank cars

October 31, 2018

How to develop a robust oversight management program

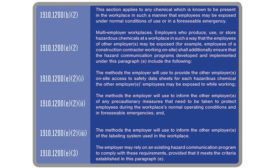

When contractors come on site

October 31, 2018

Safety signage changes after accident

7-year-old falls, killed by subway train

October 30, 2018

How I quickly assess safety cultures

Look at primary, secondary & misleading markers

October 29, 2018

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing