Featured on Home Page

Beyond glove performance

Read More

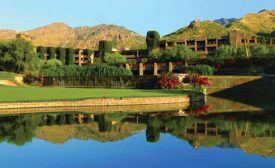

International Glove Association's 2017 Glove Symposium

March 19-21, Tucson, AZ

February 1, 2017

Cut-resistant sleeves evaluated for respiratory hazards

Shedding fibers a cause for concern

February 1, 2017

How to avoid frostbite and other winter perils

Get a handle on the weather

February 1, 2017

Assess hazards, worker likes & dislikes & current usage

Evaluate your hand protection needs

February 1, 2017

Gloves as a ‘business enabler’

Keep employees on the job, productive & motivated

February 1, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing