Featured on Home Page

A FairWarning story

Battling menthol restrictions, R.J. Reynolds reaches out to Sharpton, other black leaders

February 10, 2017

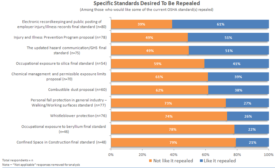

OSHA standards: to repeal or not to repeal

That is one of the questions we asked ISHN readers

February 10, 2017

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing