Home » dust hazards

Articles Tagged with ''dust hazards''

Understand NFPA 652 and new requirements for a dust hazard analysis

A dangerous dust up

March 30, 2017

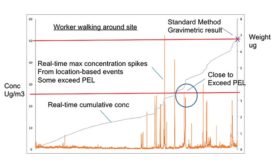

Painters exposed to dust more than 6 times OSHA’s permissible limits

Company faces $76K in OSHA penalties

December 11, 2015

Don’t let it happen: Out of sight, out of mind?

Combustible dust incidents continue while rulemaking drags

March 1, 2012

Become a Leader in Safety Culture

Build your knowledge with ISHN, covering key safety, health and industrial hygiene news, products, and trends.

JOIN TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing