Home » Combustible dust

Articles Tagged with ''Combustible dust''

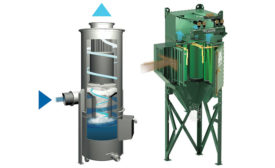

Maintenance worker burned in flash fire

OSHA: Manufacturer had four previous fires

April 8, 2016

Respiratory standard prevents serious illnesses

But inspectors assessed penalties totaling $2,731,806 in 2015

March 1, 2016

Never miss the latest news and trends driving the safety industry

eNewsletter | Website | eMagazine

JOIN TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing