Capture or continuous cleaning: It’s best to prevent dust from accumulating

An engineered approach to combustible dust safety relies on technology to solve the problem of accumulated dust. There are two types of technology for this approach:

1. Localized filtration – captures the combustible dust by either vacuuming or suctioning.

2. Barrier technology – prevents combustible dust from accumulating on overhead structures with a robotic clean fan.

An engineered approach contrasts a managed approach, where personnel or third-party business manually clean the accumulated dust on an ongoing basis

Actually, there is a third approach too. That is the decision to do nothing, as in “I don’t have to worry about combustible dust.” But I’ll get to that later.

Let me address how an engineered approach works by citing some case studies.

Case studies of an engineered approach

• Case Study #1:

Safety has always been a top priority for Cincinnati-based Cintas. (This year, Cintas merged its Document Shredding business with Shred-it’s to form a new company, which now operates under the name Shred-it.) Combustible dust had posed a potential hazard in Cintas’ document management shredding facilities across the country; therefore, when OSHA launched its National Emphasis Program on combustible dust, Cintas knew it needed a new strategy.

Cintas did its homework. First, the company assembled key employees from its engineering and safety departments to work together on the new strategy. At the Clean Show in New Orleans, members of the team had learned about clean fans that allowed for an engineered solution instead of a managed one. Cintas installed the fans throughout its plants because key company personnel thought the fan systems could deliver higher levels of cleanliness more consistently than a manual approach. As a result of the installations, Cintas has realized a significant abatement in dust accumulation on lights, beams and other horizontal surfaces. The company retained its daily housekeeping program to prevent dust accumulations on floors and equipment.

• Case Study #2:

Lehigh Technologies is a specialty materials company that produces highly engineered, versatile raw materials called Micronized Rubber Powders. As an integral part of their industrial hygiene strategy, they wanted to make sure that the risks of combustible dust were minimized to protect employees, ensure compliance, and to meet their housekeeping standards.

They spent several hundred thousand dollars on dust collection systems and explosion protection alone, and still were not satisfied. So they installed barrier technology clean fans in their overhead areas and, according to Process Development Engineer Matthew Van Der Sluys, “The results now are visibly measurable and the cost savings versus periodic cleaning are well defined.”

• Case Study #3:

Domtar is the largest integrated marketer and manufacturer of uncoated freesheet paper in North America, with 13 pulp and paper mills in North America annually producing approximately 3.4 million tons of uncoated freesheet paper, 3.5 million tonnes of market, fluff and specialty pulps. The corporation’s growing Personal Care Division has six facilities spread across the United States and Europe.

Domtar takes seriously the safety of its employees and wanted a solution to enhance their existing systems to deal with the cellulose dust generated. They chose an engineered approach with barrier technology clean fans, and found that the cleaning radius was observed at more than 60 feet in some areas. The robotic fans were combined with LED lighting, providing a strategic combination to provide fugitive dust control and mitigate a primary ignition source.

The only proactive solution

These are just three examples to prove the long-term efficacy of an engineered approach. But what is the underlying principle for its effectiveness?

It’s a simple principle: It’s better to prevent dust from accumulating than to clean it up afterwards. This can happen only with an engineered approach. Filtration systems can capture most (or some) of the dust and overhead clean fans create a barrier so the remaining dust can’t accumulate. When you have technology either capturing or cleaning the dust continuously, your dust levels are maintained below the 1/32-inch tolerance for most industries and 1/8-inch tolerance for wood and timber processors. Your facility is in compliance continuously to the stringent OSHA regulations.

You have to be careful in how the technology is used. First, the equipment has to be appropriated properly: the equipment has to be installed correctly, and the technology needs to be used continuously so process areas are clean. In addition, for the clean fans, you don’t want to robotically clean more than 90-100-foot diameters per fan because there are too many obstacles in the way, like bar joists, etc.

Now, look at the difference with a managed approach. You are cleaning up the dust after it has already accumulated. This means that at different points of the cleaning cycle, you have higher levels of accumulated dust — and risk. Your plants won’t be in compliance with OSHA. And manual cleaning, especially for overhead areas, can be burdensome and dangerous in and of itself.

What keeps us from choosing an engineered approach?

The safety issues are undeniable, but if an accident hasn’t happened in your facility, it is easy to postpone a decision to keep your employees safe because all solutions cost money at some point. We tend to stay comfortable with the status quo until something cataclysmic happens. That “external force” is the point at which decisions can easily be expedited because the consequences have forced us to act.

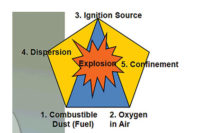

The status quo is not going to keep our employees safe from combustible dust all the time. And the cost of doing nothing is appealing only for the short term. But the consequences can be terrifying when an explosion or a fire occurs because the combustible dust has built up. Some people just don’t think it will happen in their plant. And then disaster strikes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!