“Short and cheap” is not the best fall protection training

Think of knowledge as your most valuable tool. To gain a thorough understanding of fall protection equipment and its use, a number of resources and programs are available to shorten the learning curve.

Training courses

A thorough training program is arguably the most efficient means of fall protection equipment education for any person who performs work at height. There are a variety of training options out there — some good, some bad. The challenge is in choosing a program that provides workers with a solid, well-rounded understanding of fall protection equipment, which they can easily apply to real-life situations. Generally, there are three types of fall protection training offerings:

1. Reputable, specialized. With in-depth, specialized training programs (typically offered by the equipment manufacturer), the value is well worth the price. Representatives have a thorough understanding of the equipment and can readily make informed recommendations for the customer. They also understand what the equipment feels like to wear and use, and how certain features can make or break a product in terms of comfort and user-friendliness, and consequently, the worker’s willingness to use it. Courses offered by reputable manufacturers typically meet the training standards set by ANSI.

2. Union-organized/sponsored. Union training programs are often more generic and not necessarily100-percent focused on fall protection. Think of union-sponsored training as a middle ground that equips workers with real, useful information, but is not as thorough as it could be.

3. The “one-day” wonder. Beware the “one-day” wonder, a classic example of preaching but not practicing. It may claim to fully educate and prep workers in a surprisingly short amount of time for an appealingly low price, but it does not deliver. Though typically the cheapest option, the quality of training such courses offer is unreliable at best.

As you research training options, keep in mind the most effective training programs maintain a balance between classroom and hands-on learning. Today, the classroom portion of many training programs is shifting online, giving trainees a more convenient way to learn. Hands-on experience, however, is still conducted in-person, either on the jobsite or at a training facility. Both OSHA and ANSI require workers to complete hands-on training.

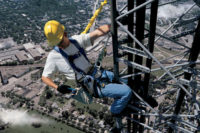

On-site courses apply professional training to specific daily work activities, which is required by OSHA. By training in and around the workers’ normal environment, you can ensure the issues discussed are immediately applicable to them. On the other hand, courses at an off-site facility provide controlled environments uniquely designed to offer practical experience. With hands-on instruction that mimics actual work conditions, workers can try out gear, experience how it feels to wear it, and see firsthand what should be inspected before use.

Demonstration vehicles

A number of manufacturers offer a demonstration vehicle service to help companies get to know fall protection equipment and to determine what models and styles will work best based on the various applications at the site. Most demo trucks can be brought directly to a jobsite to showcase a variety of equipment options and offer presentations that cover proper equipment use and inspection, as well as drop tests to help workers experience the consequences of a fall.

Educational materials

Educational materials developed by manufacturers are a great resource for those who wear fall protection gear. You can choose from a variety of multimedia, including how-to videos, guidebooks and white papers that offer lessons designed for all skill levels — from novice to expert.

Material content ranges from basic, such as an introduction to fall protection, to topical, such as how to calculate fall clearance or information on the latest standard update, to application-specific, such as guides that detail the various considerations for equipment selection within a specific industry. Manufacturers’ websites can also serve as a great information hub for technical bulletins, product instructions, owner’s manuals and more. Some sites even offer online product catalogs with the ability to filter your search to determine the ideal equipment for a given application.

The bottom line: There are many training courses and educational opportunities available, but not all of them are created equal. Don’t let cost be the deciding factor in choosing a training program. Instead, focus on quality and customization. Superior training is well worth the investment on the road to a safer workplace.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!