Wisconsin foundries address high ergo injury rates

Foundries in northeast Wisconsin have renewed a strategic partnership with OSHA aimed at improving ergonomic programs and reducing the rate of musculoskeletal injuries.

Foundries in northeast Wisconsin have renewed a strategic partnership with OSHA aimed at improving ergonomic programs and reducing the rate of musculoskeletal injuries.

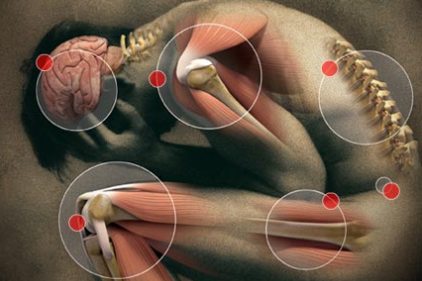

The foundry industry has a high rate of musculoskeletal and other ergonomic-related injuries due to tasks such as moving heavy equipment, material handling and the use of pneumatic equipment such as grinders and sanders. The partnership promotes continuous improvement to reduce injuries through education, hazard assessments, and the re-engineering of work stations and work processes whenever possible, as well as increasing safety and health training, and sharing best practices.

OSHA established the partnership in 2003 with Neenah Foundry, ThyssenKrupp Waupaca Foundry, Brillion Iron Works, Roloff Manufacturing Corp., Manitowoc Grey Iron Foundry and Wisconsin Aluminum Foundry Co. In addition to the original members, participants in the renewed partnership also include the Glass, Molders, Pottery, Plastics and Allied Workers Locals 121B, 271 and 301; the United Steel Workers Local 125; the International Association of Machinist Locals 516 and 1947; the Mercury Marine-Division of Brunswick Corp.; the Professional Association of County Employees Local 70475; and C.A. Lawton Co.

OSHA uses its Strategic Partnership Program to work with employers, workers, professional and trade associations, labor organizations and other interested stakeholders on specific specific goals, strategies and performance measures to improve worker safety and health.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!