Improving safety by focusing on risk management

Photo credit: mihailomilovanovic / E+ via Getty Images

Depending on the industry or nature of the business, organizations may possibly face some or all of the follow accidental losses involving property, income, liability, and employee injury. Risk management professionals are responsible for managing these risks. Those who are in the risk management arena know all about avoidance, loss prevention, loss reduction, and retention when it comes to dealing with various risks faced by their organizations. When it comes to managing the risk associated with employee safety, the risk manager usually looks to the safety department or safety manager to address that area.

Traditional safety management focuses on complying with the governing safety standards as promulgated by the state or federal jurisdiction. From this emanates the organization’s safety program, processes, procedures as well as practices. The focus of most safety programs revolves around the prevention and/or reduction of injury and/or illness involving the organization’s employees. The safety program starts off with a statement professing to value the employee and wanting to provide them with an injury-free workplace. The body of this program usually is a regurgitation of the safety standards. Some of the more developed programs may also include specialized subprograms dealing with driving for the company, dealing with the public, substance abuse, etc.

Figure #1 – Progressive risk reduction process

Image credit: Peter Furst

Traditional safety program shortfalls

One of the deficiencies of the traditional approach to safety performances management is the fact that most of the major interventions emanate from the evaluation of data regarding the previous year’s accidents and injuries experienced by the workforce. The source of this information is from internal accident investigation reports, site inspection results or data provided by brokers or insurance carriers. This analysis then establishes interventions to be devised and utilized during the coming year to reduce the accidents and resulting injuries.

The shortcomings of this approach are that the improvement strategy is based on historical data and the future conditions or situations are never exactly the same as the past. Another issue is that generally the interventions are all focused on changing the behavior of the workforce by providing more training, retraining, emphasis of certain program elements, more rigorous inspections or through providing incentives or punishment. In the short term these, efforts may result in some improvement, but in the long run, the garnered results never live up to expectations.

In general, another issue with traditional safety management emanated from the metrics utilized. The most common measurement of safety performance involves the number and type of incidents which occurred over a period of one year. The two major elements involve the frequency and severity of the incidents. These results are compared to averages published by the Bureau of Labor Statistics, or data the insurance carrier may provide. The biggest issue is that these are outcome metrics and as a result do not provide any specific information that identifies causation factors.

Another issue with the data analyzed is that it may not give a true picture of all the contributing causes, especially possible underlying ones. The loss information generally states what happened and not specifically why it happened. For this information to be of greatest value it has to answer the questions associated with what, when, where, why, who, & how. And to get at the root cause of things, these words may have to be asked a number of times especially the why (5 whys approach).

A significant benefit of controlling the costs associated with accidents is highlighted in a University of Tennessee survey of a large population of contractors which found that approximately 6 - 7 percent of the estimated cost of construction went into insurance and related expenses associated with worker safety and accidents. These same contractors reported a 1.5 percent actual profit from the same projects. It should be rather obvious that even a small reduction in the costs associated with worker safety should significantly improve these contractors’ profit margin. Discussions with the participant in the study, indicated that they grasped this concept, they did not seem to envision a structurally, effective or viable means of how to go about changing this reality.

A holistic approach

This requires a significant paradigm shift. Organizations need to look at safety more holistically, as an integrated part of the organization's activities in every endeavor; associated with operations, and not as a separate and independent function. If the organization is serious about keeping its employees injury-free and controlling the associated costs, then they not only need to look at the employees, but more importantly the physical work environment, the human dynamics, the management systems, supervisory leadership styles, as well as the organizational culture and climate. All of these in one way or another influence the employees’ motivation, engagement, behavior, job satisfaction as well as the decisions they make which sometimes may lead to an incident, injury, or loss.

The responsibility of safety personnel must change from a worker focus to focusing on risk as well as acting as safety consultant to management and various departments.

The responsibility of safety personnel must change from a worker focus to focusing on risk as well as acting as safety consultant to management and various departments. Assist people responsible for procuring work by evaluating the nature and level of risk inherent in projects under consideration, and the capability of the organization’s systems and people to adequately deal with them. Provide assistance to project staff to assess the risks associated with an acquired project, and provide input during preconstruction activities related to identification of risk and the best ways to manage and mitigate their potential impact.

They will play a key role in the planning of the project by providing input to project staff regarding the inherent risks associated with the selection of means and methods. Assist in various planning functions, such as pre-project and project construction activities, phase planning, trade, and task planning. Participate in the selection of the appropriate means and methods that will “best” deal with specific inherent risks. Provide input on assignment of potential staff regarding their capabilities in dealing with specific risks.

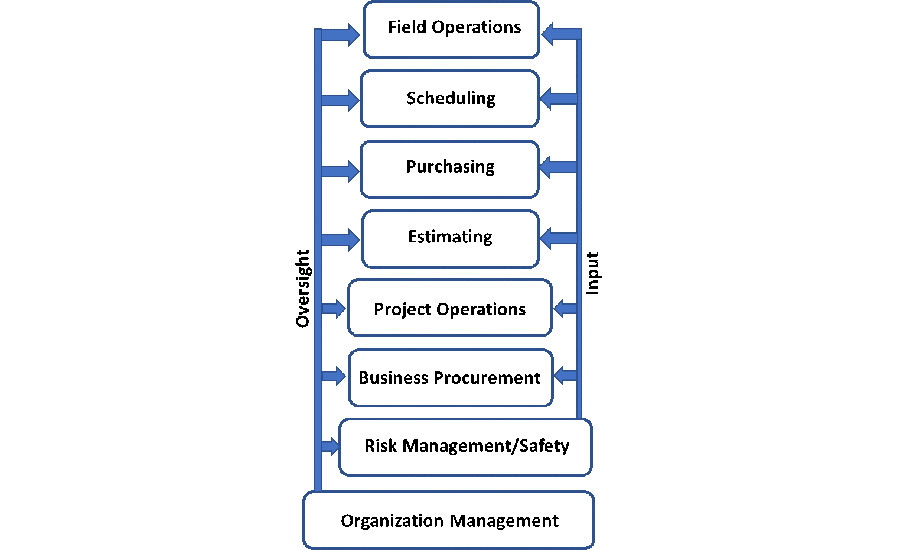

Figure #2 – Risk Management/Holistic safety input to various departments

Image credit: Peter Furst

Provide input on risks associated with the subcontractor selection process. Assist in the evaluation of risk management capabilities of critical path subcontractor field personnel and management. Participate in owner and/or subcontractor meetings where risk management issues require input. Conduct field inspections to assess state of risk management and report to senior management on outcomes and status.

Assist in project setup by providing input regarding risks associated with a new construction project in an existing neighborhood. There are issues associated with both pedestrian and vehicular traffic. Issues regarding trucks flow in and out of the site. Construction activity noise, dust, and other issues impacting the adjacent occupied area. Then there are the risks associated with job site configuration such as laydown areas, GC and subcontractor offices, parking, as well as the associated interaction of people and construction equipment. As well as other issues regarding storage, overall work flow, site security etc.

Assist in preconstruction activities. Provide risk input into business procurement activities. Risk associated with the type of project pursued in business development. Risks associated with proposed project site’s neighborhood, socioeconomic factors, neighboring usage such as schools, residential use, etc.

Just adopting one or two elements listed above can easily result in a 10% savings in the 6-7% cost of managing overall worksite safety. A ten percent saving of the six percent safety cost factor mentioned above equals 0.6% which when added to the 1.5 percent project profit equals to 2.1%. This results in a 40% improvement of the overall profit picture. The survey team followed up with a study of implementing a large number if the element listed above. They found it was feasible to garner savings in the safety cost area, equal to a twenty five percent. 25% of 6% = 1.5% which double the profit margin. The beauty of this is that all they have to do is go about doing the same things just differently.

Conclusion

This broad approach would create the best, most efficient and effective use of the safety function of the organization by providing risk input into every area. Starting with various departments such as business procurement, estimating, purchasing, scheduling, cost control, construction field operations, as well as warranty work. But it might require a more knowledgeable and versatile people to effectively carry out the broader responsibilities more effectively.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!