New way to prevent MSDs among construction workers

A rating system helped predict which solutions construction workers would use to prevent musculoskeletal disorders (MSDs), according to a study at Washington University School of Medicine in St. Louis, Missouri that was funded by the National Institute for Occupational Safety and Health (NIOSH). The study appeared in the American Journal of Industrial Medicine.

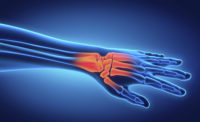

Among construction workers, the leading causes of MSDs are sudden or prolonged repetitive motions, forces, and awkward positions that damage soft tissues. Fortunately, safe and efficient work practices, or ergonomic solutions, can help prevent these disorders. At NIOSH, investigators in the NIOSH Musculoskeletal Prevention Program worked with Washington University and other partners to study ergonomic solutions to prevent musculoskeletal disorders.

In this study, three analysts, including an occupational-medicine physician and two occupational therapists, rated the likelihood that construction workers would adopt 16 different solutions to tasks that could cause MSDs. For example, one solution, pictured above, involved using an electric-powered crimper instead of a manual crimper to crimp the edges of metal pipes used for ductwork. The three analysts selected the solutions from a previous study, by the same group of investigators, testing the adoption of solutions among 86 workers from seven floor laying, carpentry, and sheet-metal companies. Using this information, as well as findings from focus groups, research observations, and interviews with contractors and industry representatives, the analysts defined barriers and facilitators to adoption.

Next, they used a 2007 rating system to score the likelihood that the construction workers and their contracting companies in the previous study would adopt each solution. The rating system includes five categories: (1) relative advantage, (2) compatibility, (3) complexity, (4) ability to try the solution (or trial ability), and (5) observability. In addition to these five categories, the analysts added usability.

Study results showed that the six categories helped predict which solutions the workers were more likely to adopt. In addition, simple solutions faced fewer barriers to use than complicated ones. Of the 16 methods tested, the rating system identified two—the power crimper and an extended pry bar for jacking up furniture—that workers would always use and 12 that they would use either always or sometimes. In the case of the power crimper and extended pry bar, study participants called using them a “no brainer” because they were so much more efficient than other methods and they worked in most situations. In fact, these tools were so efficient that a single trial convinced workers to use them.

These findings show that the rating system could help predict the adoptability of simple solutions to prevent MSDs among construction workers. For complicated solutions, however, the rating system alone may be less useful at predicting adoption. According to the investigators, predictions in these cases may require additional time, resources, and changes in work culture.

More information is available:

- Facilitators and Barriers to the Adoption of Ergonomic Solutions in Construction

- NIOSH National Center for Construction Safety and Health Research and Translation

- NIOSH Ergonomics and Musculoskeletal Disorders

- The Center for Construction Research and Training

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!