There’s more to fall protection than wearing PPE

Identify, evaluate & control

Exposures to fall hazards pose a significant risk of death or serious physical harm in the workplace. According to the National Safety Council’s 2017 Injury Facts®, falls to a lower level were the second leading unintentional fatal workplace event and the fifth leading event resulting in cases with days away from work in 2014. Employers faced with these fall hazards tend to ignore the three lines of defense and go straight to personal protective equipment (PPE) to solve their fall issues. What is needed is an understanding of the revised OSHA rule on walking and working surfaces and related fall protection consensus standards. This will not only help ensure that correct fall equipment is purchased but also ensure that all aspects of a fall protection program are addressed.

OSHA’s three lines of defense

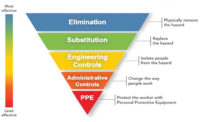

Key to helping control the risk of falling is OSHA’s “three lines of defense.” The first line of OSHA fall protection defense is to eliminate and/or engineer out the fall hazard. Engineering/elimination controls can be as simple as moving the work to ground level and eliminating the work height. Or they can be the addition of platforms, railings and toe boards to provide permanent, secure access to high maintenance areas and devices. The number of engineering controls is extensive; contact your plant engineering or maintenance department for further assistance.

When engineering/elimination controls are not feasible or practical, the second and third lines of defense can be used to help control the fall hazard. The second line of defense is administrative controls, such as employee training or written programs and policies. The third and last line of defense to be considered is personal protective equipment (PPE) – personal fall arrest systems.

Revised OSHA rule

OSHA has identified that the walking and working surfaces rule 29 CFR Part 1910 (subpart D) was outdated and simply did not provide the fall protection measures needed to adequately protect workers. The revised rule updates general industry standards addressing slip, trip and fall hazards (subpart D) and adds requirements for personal fall protection systems (subpart I). Most of the rule became effective January 17, 2017 with training requirements due six months after the effective date and fixed ladder requirements gradually phased in over a 20-year period.

Employers now have the necessary flexibility to decide which fall protection method or system works best in their workplaces. General industry employers can utilize guardrails/handrails, personal fall protection, designated areas, and safety net systems under the revised standard. The revised rule also increases consistency between the general industry and construction fall standards, which makes compliance easier for employers who conduct operations in both industry sectors. The revised rule recognizes updated national consensus standards and industry practices; that is, improved technology and extensive testing that has resulted in advanced PPE. The revised rule has been reorganized, incorporates plain language, and is performance-based making it easier to understand and follow. Full description of changes can be referenced in OSHA fact sheet 3903.

ANSI fall protection family of standards

The revision of ANSI/ASSE Z359.1 (The Fall Protection Code) received final ANSI administrative approval on August 15, 2016 and became effective of August 14, 2017.

Since the last revision of Z359.1 in 2007, many new voluntary consensus standards were developed within the Z359 series to cover various specific types of fall protection products and processes. This created a compliance “loophole” where some manufacturers chose not to follow the new equipment specific standards, yet claimed compliance with the then most current version of Z359.1. At the time, those statements were true by virtue of the fact that Z359.1-2007 did not specifically address the elements covered by the other 11 standards in the Z359 family.

The 2016 fall protection code revision closes that loophole by referencing each of the Z359 standards. To be compliant with a standard, manufacturers must meet all of its provisions. With the publication of the 2016 revision to Z359.1, all of the requirements of the 2007 standard have been superseded. As a result, manufacturers claiming to comply with the most current Z359.1 standard must now meet the provisions of the existing Z359 family of standards, which are much more stringent and protective than the elements of Z359.1-2007. The Fall Protection Code will be kept up to date as new standards and revisions are developed and published. The code requires that products meet the current version of the applicable standard when purchased. Products in use when new standards or revisions to existing standards become effective can continue to be used until they are removed from service.

So what do these ANSI standards mean to your organization? They provide a foundation to ensure that proper fall protection equipment is understood and used in your facility.

Beyond PPE

The key to any fall protection program is more than just providing fall protection PPE. PPE such as harnesses and lanyards tend to steal the show since it’s the most visible element of a fall protection program but all aspects of the revised OSHA standard must be implemented to create a safe and truly complaint fall protection system and program in your workplace. This includes training, fall hazard surveys and inspections, and procedures for identifying, evaluating, and controlling fall hazards. ANSI Z359.2 provides vetted guidance on a managed fall protection program that will help you comply with the OSHA requirements.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!