Over the years, the industry has struggled to equate cut resistance with actual risk. The recent updates to the ANSI 105 and EN 388 standards will provide a more uniformed approach to assessing the cut resistant performance of gloves across the globe. While this will make the cut scores more comparable, it will not help safety managers determine which cut score is best suited for the job. The ultimate objective of choosing the right glove for the right job requires equating a glove specification to something more realistic, like risk of injury. It is the intent of this article to outline a new and unique approach to assessing cut risk, which takes a comprehensive look at all factors involved.

Material basics and performance

Before going further, it is important that we take some time to review the basic fundamentals related to cut-resistant fibers and types of grip coatings.

Steel and glass were among the first technologies used in cut resistant apparel. While initially very strong, they were found to weaken and break after repeated flexing and gave way to the development of more advanced materials such as HPPE (High Performance Polyethylene, such as DSM Dyneema®) and aramids (such as DuPont® Kevlar®) with much higher durability. Glass and steel continue to be used today, but for the most part are now engineered with advanced materials to produce highly cut-resistant gloves and sleeves that are more comfortable, durable and flexible.

Still, depending on whether blended or engineered, we can easily go from a very inexpensive, predominantly glass blend with very high initial cut scores, to more expensive engineered yarns that make use of fully encapsulated glass, steel or mineralized materials for ultra-high cut-resistance and all-round performance. It is important to point out that, when tested, gloves made with blends of predominantly glass fibers score very high due to the dulling of the test blade. However, the inherent stiffness and brittle nature of glass fibers cause it to split, resulting in possible protection failure, skin irritation, fatigue and premature wear.

Engineered yarns

The issues described have led to the proliferation of HPPE and aramids to become the fibers of choice in providing superior cut protection in gloves and sleeves. Both materials are inherently strong with HPPE offering coolness and comfort, while aramids provide (depending on thickness) light to medium heat protection. Until most recently, this superior comfort and performance could only be gained by using higher quality HPPE and aramid-based fibers blended with spandex or nylon for extra flexibility and performance levels.

Today, the approach by leading glove producers is to develop proprietary engineered yarns, using HPPE or aramids, along with novel technology that embeds, encapsulates or blends multiple strong fibers such as glass, steel or mineral-based materials that, until recently, could not even be imagined – let alone mass-produced. Advancement in nanotechnology is allowing them to work with incredibly strong materials, previously thought to be too thick or too stiff. These natural materials can now be formed into nano-thin, highly flexible fibers that when blended to produce a whole new generation of gloves and sleeves, offer sustainable performance and dexterity.

Protection from injuries

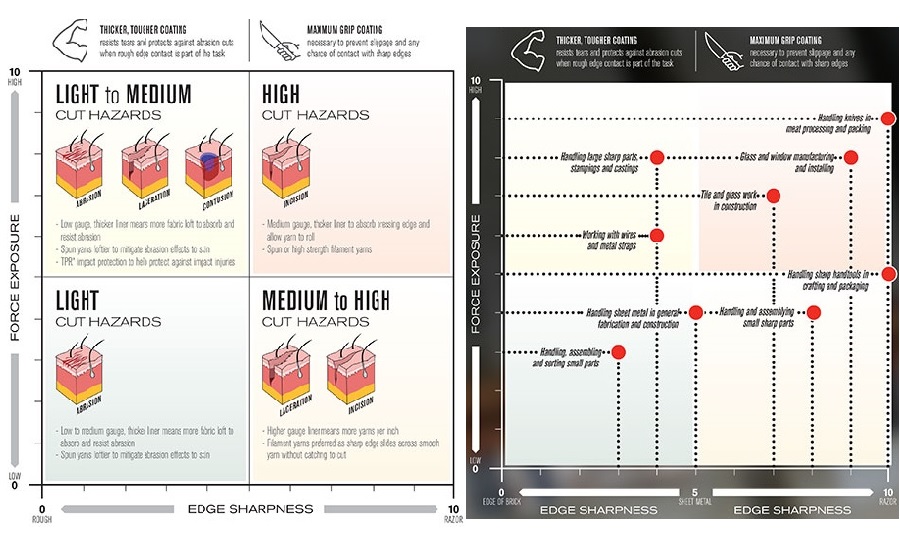

With the advancement in materials, we can feel confident that gloves and sleeves produced today are among the best we’ve ever seen. However, making the right selection only gets harder with more choices. Cut scores cannot be relied upon as the sole indicator of performance and we must consider factors in real work applications like the threats of applied force and edge sharpness and equate them to the risk of injury.

With the exception of contusions, most skin injuries are a result of contact with a sharp edge or even a burred, rough edge on fragile skin. Using a glove or sleeve layer helps reduce the likelihood of damage to the skin. The extra layer offered by a technical glove today consists of a knitted or fabric liner, coated with a natural or synthetic rubber polymer. While leather may offer some abrasion protection, it slices effortlessly when in contact with a sharp edge.

In the case of coatings, thicker, tougher varieties will offer extra protection especially when contact with burred, rough edges is a necessary part of the task. An example of this would be handling heavy sheet metal or working with castings. The coating grip also plays an important part in preventing a sharp part or knife from slipping and allowing its blade or cutting edge from making direct contact with the gloved hand or arm.

It can be argued that a cut-resistant liner should act as the last line of defense for protecting skin and that avoiding any direct contact with sharp edges is obviously crucial. Edge sharpness and force of contact are critical factors in determining whether the glove or sleeve material type will be able to defend against contact with the underlying skin. Proper selection is multi-factorial and for this reason we deemed it necessary to develop an alternative approach to help determine the risk and possible severity of an injury.

Conclusion

Selecting cut-resistant gloves or sleeves is not a linear science and choosing the highest cut level is not necessarily the best protection or best product for dexterity and productivity. We all seek a “one product - one level solution,” but that is just not possible – even with today’s advanced fiber materials and engineered yarns. By offering a more relatable method of assessing risk, we can help safety managers more confidently assess their requirements and better correlate them to EN and ANSI cut scores.