Since OSHA does not clarify what the minimum requirements for “suitable facilities” are, employers look to the voluntary American National Standards Institute (ANSI) Z358.1-2009 Standard for Emergency Eyewashes and Shower Equipment for guidance. ANSI Z358.1-2009 helps users select and install proper emergency equipment to meet OSHA requirements. Also, OSHA often uses ANSI Z358.1 as a guide during inspections and may elect to issue penalties for those found not to be in compliance.

ANSI Z358.1-2009 Requirements

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in Z358.1-2009 be followed.

ANSI Z358.1-2009 is divided into five sections and each section addresses how the equipment should perform, as well as testing procedures for ensuring proper operation, installation, maintenance and training.

The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the units should be inspected and tested and the results recorded weekly. Individual owner manuals should be reviewed for the specific manufacturer’s guidelines.

Plumbed and Self-Contained Emergency Showers, Eyewash Equipment, Eye/Face Wash Equipment and Combination Units Performance and Maintenance Criteria:

- Valve should easily activate in a second or less and remain open on its own until it is intentionally turned off

- If a potential for freezing exists, product specifically designed to avoid freezing should be used

- Plumbed units should be activated on a weekly basis long enough to ensure that flushing fluid is provided

• Plumbed and self-contained showers must maintain a minimum flushing fluid of 20 gallons per minute (GPM) at 30 pounds per square inch (PSI) for 15 minutes

• Plumbed and Self-Contained Eyewash Equipment must maintain a minimum flushing fluid of 0.4 GPM at 30 psi for 15 minutes

• Eye/Face wash equipment must maintain a minimum flushing fluid of 3 GPM at 30 PSI for 15 minutes

- Determine that flushing fluid is tepid (between 60 – 100°F)

- Determine that flushing fluid is dispersed throughout the required pattern

- Showers, eyewashes, eye/face washes, and drench hoses all can be utilized in combination units and the requirements of each of these types of product categories must be met when utilized with other categories of emergency equipment

- Self-contained units should be visually inspected and needed fluid replacement determined

Supplemental Equipment

- Supplemental equipment is intended for immediate use and must be followed up by the usage of emergency product that can provide a minimum of 15 minutes of flushing fluid continuously

- Personal eyewash units and drench hoses are considered supplemental equipment

Annual inspections

Each year emergency products must be inspected to ensure they comply per the ANSI standard. While a fixture may be certified to meet the ANSI standard, once installed, it is important to make sure it is installed according to the standard's requirements.

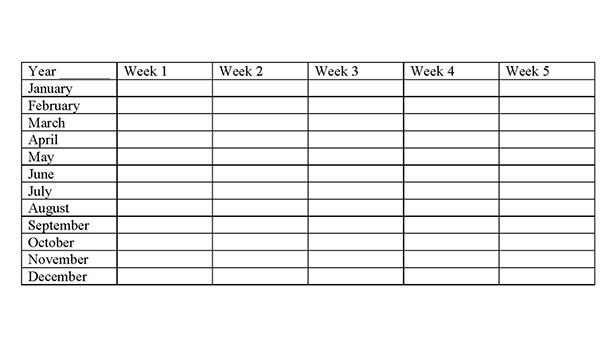

Weekly checklist

- Initial and date in the corresponding box verifying that the emergency eyewash/shower is checked weekly to ensure:

• Equipment is installed within 10 seconds from the hazard and on the same plane as the hazard

• Pathway is clear of obstructions

• Equipment is activated to ensure compliant operation and to clear any sediment

• Equipment is free of broken or missing parts

• Equipment is protected against freezing

• User is protected from scalding water

Save critical seconds

Always inspect and test emergency eyewashes and showers if there is any doubt about their dependability. Identify problems or concerns and establish a regular maintenance program. Consult the manufacturers’ operating manual and ANSI Z358.1-2009 for guidance on test procedures, maintenance, operation and training.

Inspection, testing and maintenance of the emergency eyewash/shower equipment helps ensure that it will function properly when needed. Studies show that the seconds immediately following an eye or body injury caused by a corrosive are often critical to minimize damage.